Documented Early History

the “Saw Mill Enterprise”

The documentation of the mill’s construction is found in the diary of Dr. Horace Amelius Barrows, a local Bolsters Mills’ physician and an investor, with his brothers Worthy and George, in the “Saw Mill Enterprise”.

The following entries from Dr. Barrow’s diary chronicles the mill’s earliest beginnings:

“Fryday 6 November 1846 - Bro. Worthy and his crew have been down today and laid the corner stone or foundation stone of the new city at Carsley’s Falls”.

“Monday 12 July 1847 - At 3 pm I set off for the new Mill Dam down river as this afternoon was the time appointed for the raising of the new saw mill”

“Fryday 15 October 1847 - Bro. Worthy has been up this evening and informs us that our new Saw Mill has commenced its specific operations this day by sawing a yellow birch for Headstock”.

The diary tells us that, by 1849, Bro. Worthy had tired of the saw mill business and would be willing to sell it for less than what he had invested. In January 1851, the mill was sold to his mill man, Elijah Scribner and his son Cyrus. From 1851 through 1962, three generations of Scribners owned and operated the mill and two additional generations worked in the mill.

- H. A. Barrow diary, property of the Maine Historical Society Portland, ME. -

The Scribner Family

Cyrus Scribner was 42 when he married Hannah Prince and three sons were born of this union. Jesse, the second of three sons, was born in 1870. Cyrus continued to operate of the mill for eight years after the death of his father, Elijah. By 1884, Cyrus was physically unable to operate the mill and turned its operation over to his two young sons Bourdon, age 16, and Jesse, age 14.

It was not long before the two brothers had started to modernize and enlarge the mill. In addition to the mill on the Crooked River, they expanded their business to include mills in Norway and Roxbury, Maine.

In 1895, the two brothers invested in a saw mill in northern Florida. As fortune would have it, that next March a freshet (flood) took out the northeast corner of the mill. When the brothers were called home to “see to” the repair of the mill, they walked away from their Florida venture never to return. Bourdon eventually purchased and operated a mill in East Hiram while Jesse continued the operation at Scribner’s Mill.

The peak of operation at Scribner’s Mill started during the First World War and continued to the end of the Korean War. In addition to the usual line of lumber products, the mill manufactured shook (box parts) which were used for shipment of ammunition abroad.

Jesse Scribner

As Jesse aged, modern technology revolutionized the lumbering business and the old mill was unable to compete. Jesse eventually limited his work to the manufacturing of wood shingles. It was not until the age of 92, that Jesse retired and his grandsons stopped hauling-in logs from the mill pond for him. He died in 1970 just shy of his 100th birthday.

The Mill

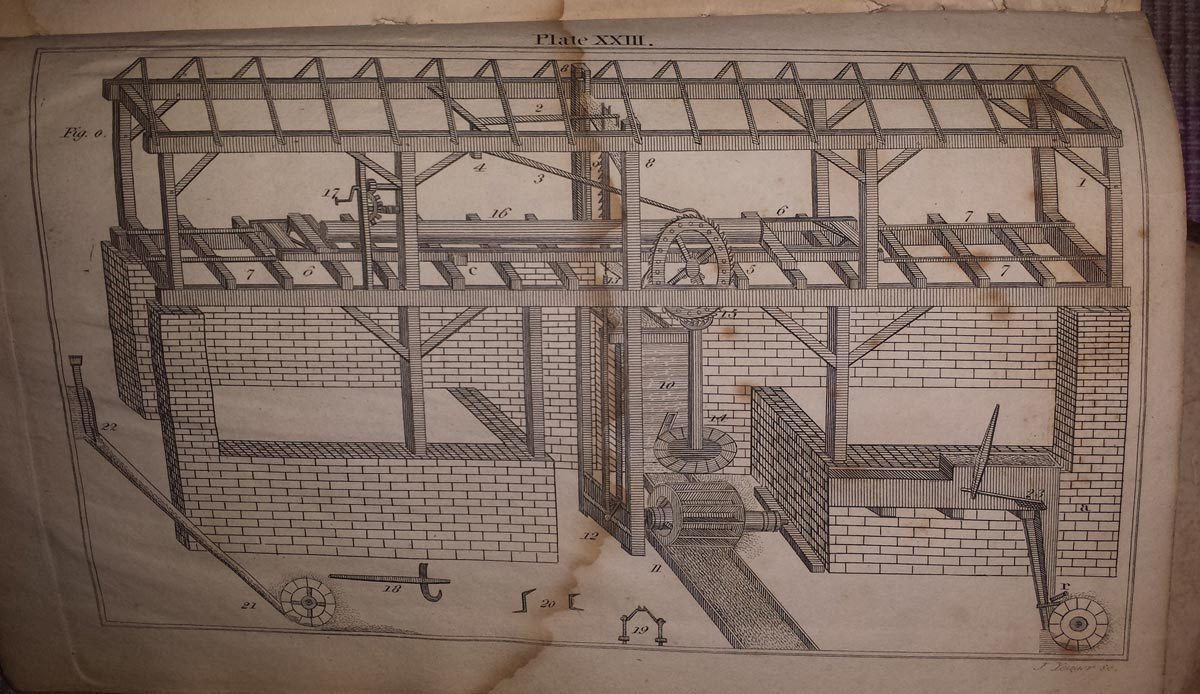

This structure evolved in three stages. The original 1847, 25' x 60' mill building contained a log ramp, haul-in wheel, log carriage, sash saw, and a circular dragon (cut off saw). In 1863, a tool room was added on the west side of the building as well as a south addition used for the manufacturing of shingles and barrels. The west ell was added in 1916 for the introduction of a lathe used for the manufacturing of Peavey handles, etc.

Our Vision

Mission Statement

To preserve a rural Maine sawmill and homestead, providing educational opportunities related to the life and times of a family operated farm and lumbering business.

Vision

Scribner’s Mill Preservation, Inc. includes the 1847 historical mill, with its sawdust shed, long shed, and blacksmith shop, and the 1849 Scribner Homestead with attached barn, icehouse, and other exhibit sheds. This multiple use site will be used for recreation, historic interpretation, and as an education center to teach the importance of the local sawmill on the surrounding community.

There will be programming at various scheduled times to draw guests to the site. Local schools will be encouraged to use our site for learning experiences. SMPI’s website will include information of the site with interpretative videos and photos of the homestead and mill site including log drives and floods.

The mill site will be open to the public to demonstrate antique machinery used and types of products produced from its early beginnings in 1847 until it closed in 1962 including lumber, shingles, turned handles, barrels, clapboards, and shook (box parts).

The original 1846 blacksmith shop with its huge bellows was the first building on site and provided temporary housing for the workmen. The blacksmith shop was essential for producing tools for building the original dam, keeping the rock drills sharp and for keeping the oxen shod. The reconstructed Blacksmith Shop will house early American tools and include demonstrations by local blacksmiths.

The Scribner Homestead will be open for guided tours which will include artifacts from the 1920’s era and stories related to the Scribner family and the millworkers that were an integral part of the mill.

Stories from the Past

BARRELS SOLD IN 1896 AT SCRIBNER’S MILL

In an 1896 ledger, Jesse Scribner kept an account of barrels sold to local farmers who packed their apples into the barrels for shipment to customers in England. The apple variety was Baldwins, we have been told that by the time this tart apple reached England they would be just right for eating.

In 1896, 170 orders were filled which equaled 10,124 barrels sold at .35 each. A deep freeze in 1938 of 50 degrees below zero froze the apple trees and ended the barrel making business at Scribner’s Mill. The equipment was discarded or sold, and the manufacture of shook (box parts) replaced that of barrels. As a part of the War effort, shook was sent to factories that manufactured ammunition during World War II. The box parts were also sold for use in the canning industry.

Jumping forward to 2013, surprisingly it has been difficult to keep up with the demand for the dry barrels made at Scribner’s Mill at the price of $40 a barrel.

In the fall of 2014 we were invited to bring our barrel making equipment to Portland to participate in Victorian Days and to Freeport’s Old Farm Days.

RESTORING SCRIBNERS MILL

Article from Memories of Maine

Written in cooperation with Marilyn Hatch

Published in 2014

For the last 40 years a group of dedicated volunteers, members of Scribner’s Mill Preservation, Inc., have been working to restore Scribner’s Mill, a sawmill located along the Crooked River in Harrison, Maine, back to working order.

“What this group wanted to do was restore the mill as an industrial site that demonstrated the different products produced at the mill from its early beginnings throughout its history.

Scribner’s Mill, like many other early sawmills across the country, played an integral role in establishing a community. They were usually the first structure built to provide the wooden products required to build the town. This mill was no different. From the beginning it not only produced dimension lumber, but also clapboards, shingles and lathe, whatever was needed to build a house except for the nails, plaster and hardware, where there was a community, there was a saw mill.

Scribner’s Mill has a long history in Harrison, dating back to 1847. The sash [Up & Down Saw] sawmill was started in a 30 x 60 foot building built by Worthy Barrows and financed with help from his two brothers George and Dr. Horace Barrows, a local Bolsters Mills physician.

Dr. Barrows was in the habit of keeping a daily diary. According to a diary entry, by 1849 Brother Worthy had tired of the sawmill operations and was willing to sell it for what he had invested. In January 1851, Worthy sold this enterprise to his sawyer, Elijah Scribner and Scribner’s son, Cyrus, for less than what was originally invested. The diary is housed in the library at the Maine Historical Society in Portland. It’s fairly rare to have a historical site that has written documentation of its early construction.

The mill has passed from one generation to the next in the Scribner family until 1962 when it ceased operations.

During its years of operation the mill underwent a series of alterations. In 1860 a tool room was added to the west side of the building and a southern addition was constructed to accommodate the manufacturing of wood shingles and barrels. In 1890, the sash saw was swapped for a circular saw. An ell addition was added to the building in 1916.

According to scribnersmill.org, in 1884 Cyrus was “physically unable” to operate the mill and turned over its operations to his young sons, Bourdon, who was 16 and Jesse, who was 14. When Cyrus could no longer work in the mill he told his two young sons, Bourdon (sixteen) and Jesse (fourteen), that they had to take over running the mill to support the family.

The mill and the lumber business were a familiar place for the brothers.

“These boys were brought up in close acquaintance with all the various branches of lumber-sawing from log to finish, and so level-headed and capable that they took up the work and the responsibilities devolving upon them, as the natural successors of their father,” read an excerpt on the Scribner family in Centennial History of Harrison, Maine.

The scope of work at the mill increased under Bourdon and Jesse’s tenure and it wasn’t long before the brothers began to modernize and expand the mill’s operations. Bourdon and Jesse “diversified the mill” by manufacturing a variety of products. One such product was barrels that were made for the local apple industry. In a ledger dated 1896, Jesse kept a log that recorded the number of barrel orders and the barrels produced. He had recorded 170 orders for 10,124 barrels sold at .35 to local farmers. The Baldwin apples were packed in the barrels and shipped to England where they were a sought after product.

In the winter of 1938, a deep freeze hit the area that froze the apple trees.

Then in September, of the same year, New England suffered through a hurricane that blew down thousands of acres of trees. This event is referred to as the “Blow Down.” The remaining apple trees were also a casualty of this hurricane.

The apple industry in the area ended as well as the demand for the barrels made at Scribner’s Mill. Rather than dwell on that unfortunate event, the brothers turned their focus to other products such as making shook (box parts), Peavey handles, wood silos, and table leg blanks.

“The peak operation at Scribner’s Mill started during the First World War and continued to the end of the Korean War,” according to the website. “As a part of the WWII war effort, the mill manufactured shook (box parts), used for the shipment of ammunition abroad.” The box parts were shipped to the munition factory where they were assembled and packed.

Jesse usually had a crew of 18 men working for him and during the winter he always kept one man on to help him cut shingles. As he aged, he depended on the younger men to do the heavy work, but he always assigned himself some sort of job. One of the things he liked to do was walk the logs on the mill pond. In his 90's, you could find him out on the pond with his “pick pole”, a long pole with a hook on the end, selecting the logs that were to be hauled into the mill to be sawed.

As Jesse aged, he was unable to keep up with the advances in technology revolutionizing the mill industry in his old building.

“It was not until the age of 92 that Jesse retired and his grandsons stopped hauling logs from the mill pond into the mill for him. According to the website, he died in 1970, just short of his 100th birthday.”

Four years later, a group of volunteers decided the mill should be preserved and a nonprofit organization to do just that was formed in 1975.

In 1975 the restoration of the mill began with the hope that they would restore it using the sash saw rather than the circular saw.

Doing so wouldn’t be easy for the group.

In the summer of 1976 high summer water and a cold winter produced thick ice on the river. The spring rain broke the ice up and carried the blocks of ice down the river through a breech in the dam that crashed into the center pier of the mill causing the river side of the mill to collapse.

After it collapsed in 1977, it was decided that the site was historically important enough to reconstruct the mill. Luckily, John Hatch, founding member, had taken the time to create measured drawings of the mill prior to its collapse which was critical in creating an authentic reconstruction.

The mill is not listed on the National Register of Historic Places, although that “doesn’t diminish its historic significance for Maine.”

The reconstruction work, most of the materials used, and the funds to accomplish the work has taken place thus far has come through the efforts of volunteers. As an example one member of the board of directors, who owns a wood lot, has been very generous in providing the materials for the shingles and barrels that are produced at the mill today. Another member has heavy equipment need for its construction. Another manages the web site. Each person brings their own special talents to the organization.

In 2002 the preservation group started the permitting process to construct a six-foot dam on the river. Immediately, this proposal was met with opposition from State Agencies, so the group proposed a nature-like fishway giving a three foot head of water. All permitting has been denied in part due to the impact it would have on the river’s fish population.

According to a 1982 Maine Rivers Study, the Crooked River is one of “the state’s most significant inland fishery rivers”. The following year, according to mainerivers.org, the 1983 Rivers Act “designated the Crooked River as worthy of special protection because of its value as a fishery resource.”

At this point in our restoration, there is a lot of work to do and considerations to be made to come up with something that is going to operate the mill.

In an effort to better get a feel for antique sawmills like Scribner’s, in 2011-2012 both Mr. and Mrs. Hatch visited and documented 32 sites associated with Sash Sawmills in states from Michigan to Virginia, Illinois to Maine. This research gave a glimpse of the mill landscape and confirmed the notion that Scribner’s Mill is one of a kind as the last remaining family owned and operated early industrial operations providing wood products to the local and national markets.

The mill is active throughout the spring, summer and fall seasons hosting school class field trips, continued educational groups, and tours to senior citizens and historical society members. The site is open to the public the first and third Saturdays of the month from Memorial to Labor Day. Besides the mill, the site includes a long shed that presently holds the shingle mill, wagons and other mill equipment; a saw dust shed where sawdust was stored until it could be removed from the property; and a blacksmith shop. The blacksmith shop was the first building on site and was used to sharpen the drills used to cut granite for the mill foundation and dam. It was always important in providing the metal work needed for the mill.

The Scribner homestead is on the opposite side of Scribners Mills Rd. It is a two-story house built in 1849. It is also incorporated into the educational offerings. The Hatches bought the home, where five generation of Scribner’s lived from 1850 to 1983, and have preserved the first floor as it appeared in 1924 when it was remodeled.